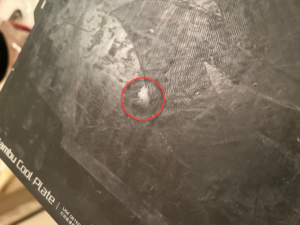

So roughly 50 prints later, I’ve learned a couple things that may be helpful in your printing journey.

- Glue matters. Your new print plate will adhere a little too well to the print. Using the Bambu provided glue stick will help make your part easily removable. However, if you find that you’re running low on their branded glue stick, I’d caution you to be careful about which glue stick you use as a substitute. In this case, I used an Elmer’s glue stick. Right away, applying the glue, there was an immediate difference in texture. This particular selection of Elmer’s leaves a thicker, choppier coating of glue. The Bambu glue stick goes on much thinner, creating a sheen surface. After printing onto the Elmer glue surface, the problem arose when trying to remove a large print surface from the plate. The glue was notably stronger, making the part more difficult to remove. Consequently, it caused the sacrificial sticker to lift and bubble from the plate surface. The lesson learned is to stick with the Bambu glue if you can or avoid large prints with the Elmer’s. There are many other glues out there that may perform as well or better, but the ones I’ve seen are more expensive.

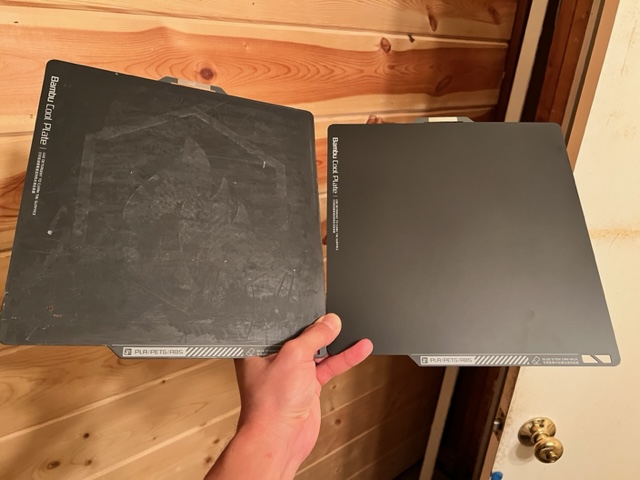

- A smooth, clean print plate is optimal for print quality. With a bubble in my print plate, it predictably disrupts the usually pristine print surface. This probably weakens the print as well, which means I need to replace the sticker surface. Fortunately, I had ordered a backup print plate while I worked on replacing the cool plate sticker.

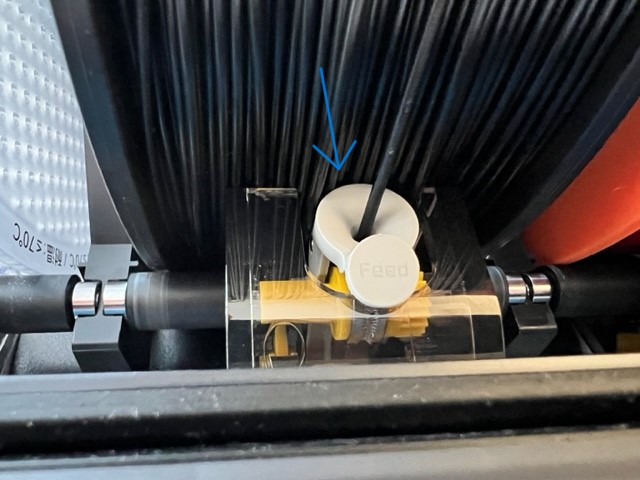

These are the two glues I compared.

Elmer’s goes on a little messier, with a thicker, choppier coating.

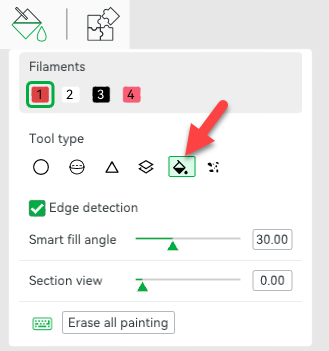

Left is the older print plate, after about 50 prints. On the right, is a brand new plate.

The consumable print surface is lifted, resulting in a bubble.

Usually, the 1st print layer is nice a smooth, but with the bubble, it comes out distorted.